Features

The Difference Between Instant Noodles And Other Noodles

The Difference Between Instant Noodles And Other NoodlesThe distinct deference between instant noodles and other noodles is the drying process. Fried instant noodles are dehydrated by oil frying, which not only make the noodles a long duration (above 6 months), but also make the product completely aging, and then the finished product can be immediately cooked with hot water but no need to boil it. The main raw material is wheat flour (protein containing is above 10%), other material included edible salt and edible soda. Palm oil is always used for frying, since it has merits of nice anti-oxygenation, stable function, durable, economical.

Production Process of Instant Noodles

The process of fried instant noodles is not complex, since the equipment has been standardization through an automated instant noodles production line. The whole line running full automatic from raw material and packing under PLC and encoder in-phase controlling system, which make the whole production procedure mechanized, including add how many water and flour, flour mixing time, aging time, steaming time and frying time, etc. The technical parameters such like temperature are all set in the electric control panel in advance, and the worker just need to press the button. This is a production line with high autoimmunization, stable function and easy operation; you don’t need to worry about how to control it. As providing fully automatic production line, we will also send engineers to your factory for machine's installation &commission and training your workers, and we are very confident to be a good partner (supplier) of yours. The capacity of 600,000 bag per shift(8 hours), This will be an opportunity to enter the noodle processing business and challenge the dominance of Indomie noodle.

Bag Packing And Cup/Bowl Packing

With regard to the packing, nowadays, there are two kinds. One is bag type, that is plastic film is used to pack the noodle cake, the equipment is simple and high automatic and low cost. The other one is cup/bowl packing, it is more complex than bags packing, first you should get the cup or bowls form professionally manufacturer, and this packing machine can be semi-automatic and all-automatic, it is very expensive, price of semi-automatic one is 4~5 times as bags packing machine. Since your project is new, and you are not familiar with the market, we highly recommend you choose bag packing, after you test the market, you can consider cup/bowl packing

With regard to the packing, nowadays, there are two kinds. One is bag type, that is plastic film is used to pack the noodle cake, the equipment is simple and high automatic and low cost. The other one is cup/bowl packing, it is more complex than bags packing, first you should get the cup or bowls form professionally manufacturer, and this packing machine can be semi-automatic and all-automatic, it is very expensive, price of semi-automatic one is 4~5 times as bags packing machine. Since your project is new, and you are not familiar with the market, we highly recommend you choose bag packing, after you test the market, you can consider cup/bowl packing

Technical Data

Dividing glaze width:350mm Production: 60000 bags/ 8h (55 g/piece)

| Equipment | Specification |

| Brine metrology mixer |

Power 1.5 kw Capacity: 100 L/units |

| Double speed dough mixer |

Power: 9/11kw 200kg/pot |

| Disc curing machine |

Power: 4kw Tray: φ2000mm*410mm |

| Dough rolling machine |

Power:5.5kw+5.5kw 7 pair steel roller frequency control |

| Single-layer steaming machine |

24meters, water seal, Main drive 1.5 kw fan0.37 kw×2set |

| Cutting and folding machine |

Main drive 1.5 kw air knife:0.9 kw |

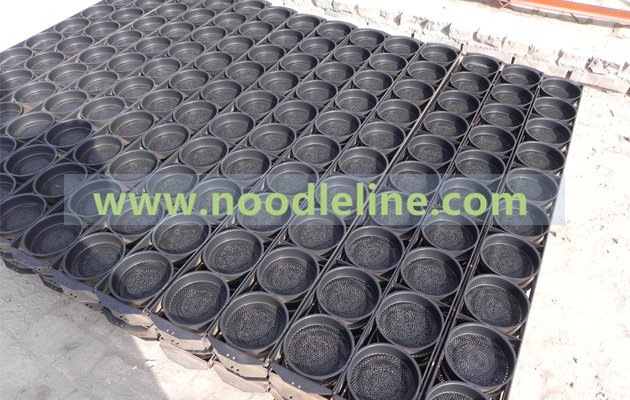

| Fried dryer | Main drive 2.2 kw |

| Air cooling device |

Fan:0.37 kw*10set, exhaust fan:3kw |

| Variable conveyor |

Main drive 0.37kw*2 (frequency control motor speed) |

| Products conveyor | Main drive 0.37 kw |

| Electric control cabinet |

Frequency control of motor speed PLC program control |

Message

Message